Understanding OMS, WMS, and TMS: A Comprehensive Guide

When it comes to managing logistics and supply chain operations, three acronyms stand out: OMS, WMS, and TMS. These systems are crucial for businesses looking to streamline their operations, reduce costs, and improve efficiency. In this article, we will delve into the details of each system, highlighting their unique features and how they can benefit your business.

What is OMS (Order Management System)?

An Order Management System (OMS) is a software solution designed to manage the entire order lifecycle, from order intake to fulfillment and beyond. It serves as a central hub for all order-related activities, ensuring that every step is tracked and documented. Here are some key features of an OMS:

-

Order intake and processing

-

Order tracking and status updates

-

Inventory management

-

Customer relationship management (CRM)

-

Reporting and analytics

OMS helps businesses automate and optimize their order management processes, leading to improved customer satisfaction and increased sales.

What is WMS (Warehouse Management System)?

A Warehouse Management System (WMS) is a software solution designed to manage the day-to-day operations of a warehouse. It helps businesses track inventory, optimize storage space, and streamline picking, packing, and shipping processes. Here are some key features of a WMS:

-

Inventory tracking and management

-

Storage optimization

-

Picking, packing, and shipping processes

-

Real-time reporting and analytics

-

Integration with other systems (e.g., OMS, TMS)

WMS enables businesses to improve their warehouse operations, reduce costs, and enhance overall supply chain efficiency.

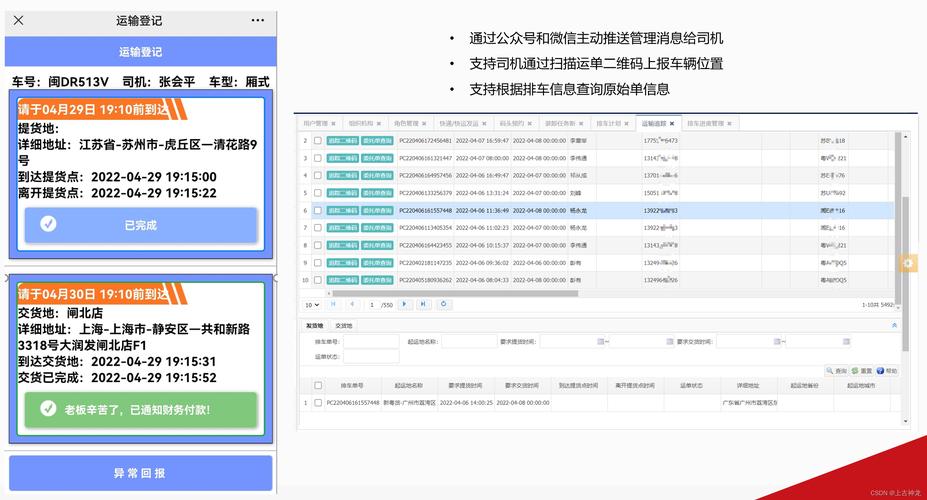

What is TMS (Transportation Management System)?

A Transportation Management System (TMS) is a software solution designed to manage and optimize transportation operations. It helps businesses plan, execute, and track their transportation activities, ensuring that goods are delivered on time and within budget. Here are some key features of a TMS:

-

Transportation planning and optimization

-

Carrier selection and management

-

Freight auditing and payment

-

Real-time tracking and reporting

-

Integration with other systems (e.g., OMS, WMS)

TMS helps businesses reduce transportation costs, improve delivery times, and enhance customer satisfaction.

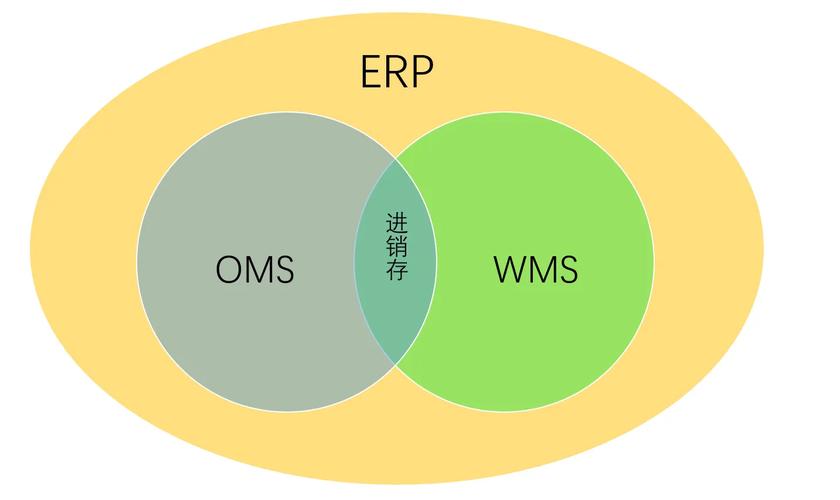

How OMS, WMS, and TMS Work Together

While OMS, WMS, and TMS are distinct systems, they are often used together to create a seamless and efficient supply chain. Here’s how they work together:

-

OMS receives an order from a customer and sends it to the WMS for processing.

-

The WMS manages the inventory and determines the best location for the order.

-

The WMS then sends the order to the TMS for transportation planning.

-

The TMS selects the appropriate carrier and schedules the delivery.

-

The OMS keeps the customer updated on the order status throughout the process.

This collaboration ensures that every aspect of the supply chain is optimized, from order intake to delivery.

Benefits of Integrating OMS, WMS, and TMS

Integrating OMS, WMS, and TMS can bring numerous benefits to your business, including:

-

Improved efficiency: Streamline your supply chain operations and reduce manual processes.

-

Reduced costs: Optimize transportation and inventory management to lower expenses.

-

Enhanced customer satisfaction: Provide accurate order tracking and timely delivery.

-

Better decision-making: Gain insights from real-time data and analytics.

By integrating these systems, you can create a cohesive and efficient supply