Understanding OMS SCADA: A Comprehensive Guide

SCADA systems have become an integral part of modern industrial operations, providing real-time monitoring and control of various processes. One such system is the OMS SCADA, which stands for Operations Management System Supervisory Control and Data Acquisition. This article delves into the intricacies of OMS SCADA, offering a detailed overview of its features, applications, and benefits.

What is OMS SCADA?

OMS SCADA is a sophisticated system designed to monitor and control industrial processes. It combines the functionalities of a Supervisory Control and Data Acquisition (SCADA) system with an Operations Management System (OMS). This integration allows for efficient management of operations while providing real-time monitoring and control capabilities.

Key Components of OMS SCADA

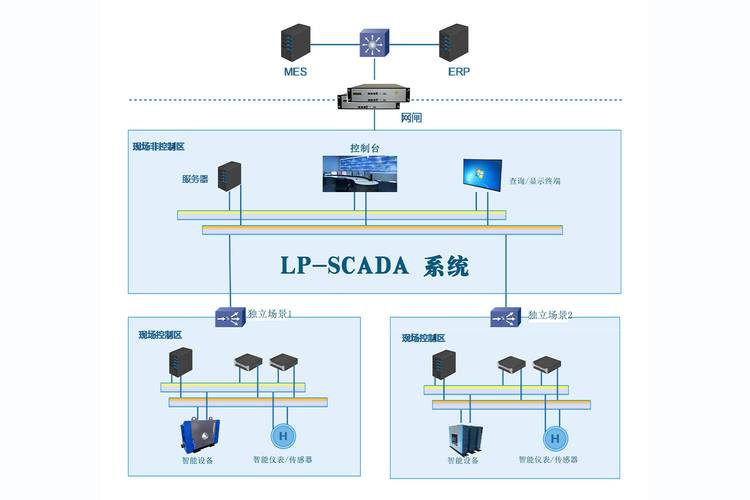

OMS SCADA consists of several key components that work together to ensure seamless operation:

| Component | Description |

|---|---|

| SCADA System | Monitors and controls industrial processes in real-time, providing data acquisition and visualization capabilities. |

| Operations Management System | Manages and optimizes operations, ensuring efficient resource allocation and process control. |

| Human-Machine Interface (HMI) | Enables operators to interact with the system, providing a user-friendly interface for monitoring and controlling processes. |

| Communication Network | Facilitates data transfer between various components of the OMS SCADA system. |

Applications of OMS SCADA

OMS SCADA systems are widely used in various industries, including:

- Power Generation and Distribution

- Oil and Gas Production

- Water and Wastewater Treatment

- Chemical Manufacturing

- Transportation and Logistics

Benefits of OMS SCADA

Implementing an OMS SCADA system offers several benefits, such as:

- Improved Process Control: Real-time monitoring and control enable operators to make informed decisions, leading to improved process efficiency.

- Enhanced Safety: Early detection of anomalies allows for timely intervention, reducing the risk of accidents and equipment failures.

- Cost Reduction: Efficient resource allocation and process optimization can lead to significant cost savings.

- Increased Productivity: Streamlined operations and reduced downtime contribute to higher productivity levels.

Implementation of OMS SCADA

Implementing an OMS SCADA system involves several steps:

- Identify the requirements: Determine the specific needs of your organization, including the processes to be monitored and controlled.

- Select the appropriate hardware and software: Choose the right components that meet your requirements, such as SCADA software, OMS software, and communication devices.

- Design the system architecture: Plan the layout of the system, including the placement of sensors, controllers, and communication networks.

- Configure the system: Set up the SCADA and OMS software, ensuring that all components are properly integrated.

- Test and commission the system: Verify the system’s functionality and performance, making any necessary adjustments.

Conclusion

OMS SCADA systems offer a powerful solution for monitoring and controlling industrial processes. By integrating SCADA and OMS functionalities, these systems provide real-time data acquisition, process control, and operations management capabilities. As industries continue to evolve, the adoption of OMS SCADA systems is expected to grow, enabling organizations to achieve greater efficiency, safety, and productivity.